Copper Sheet Roll

Price 250 INR/ Roll

Copper Sheet Roll Specification

- Copper Thickness

- 3 Millimeter (mm)

- Product Type

- Sheet Roll

- Material

- Pure Copper

- Application

- Industrial

- Surface Treating

- polished

- Color

- Copper

Copper Sheet Roll Trade Information

- Minimum Order Quantity

- 1 Roll

- Supply Ability

- 100000 Rolls Per Month

- Delivery Time

- 4 Days

About Copper Sheet Roll

Premium Quality Pure Copper Sheet Rolls

Our copper sheet rolls are meticulously manufactured from pure copper, ensuring durability and consistent performance in demanding industrial settings. The 3 mm thickness provides remarkable sturdiness for various applications while the polished finish gives an impressive, professional look.

Versatile Industrial Applications

Engineered for versatility, our copper sheet rolls are perfect for electrical systems, construction, and fabrication needs. The inherent conductivity and corrosion resistance make them an excellent choice for both functional and decorative uses in diverse industries.

FAQs of Copper Sheet Roll:

Q: How are the copper sheet rolls manufactured and finished?

A: These copper sheet rolls are produced using high-grade pure copper through a precision rolling process. After shaping, the surface is polished, giving the sheets a smooth, reflective finish that enhances both performance and appearance.Q: What are the primary industrial applications for this copper sheet roll?

A: This sheet roll is widely used in electrical projects, architectural fab, heat exchangers, and general engineering. Its superior conductivity and corrosion resistance make it invaluable in sectors requiring robust, reliable metal solutions.Q: When should I choose a 3 mm thickness in copper sheet rolls?

A: A 3 mm copper sheet is ideal for applications demanding extra strength and rigiditysuch as heavy-duty electrical components, protective coverings, or structural elementsthat can benefit from enhanced durability without sacrificing conductivity.Q: Where can these copper sheet rolls be supplied from?

A: We are based in India and supply copper sheet rolls locally and internationally, catering to the needs of industries worldwide through a robust export network.Q: What is the process for ordering from an exporter, manufacturer, and supplier in India?

A: To place an order, contact us directly with your specifications. Our team offers prompt quotations, seamless processing, and efficient shipment, ensuring timely delivery whether for local use or international export.Q: How is the copper sheet roll best utilized in industrial settings?

A: The sheet can be easily cut, shaped, or welded for custom applications in electrical busbars, architectural cladding, and various fabrication projects, leveraging its strength and conductivity to meet rigorous industrial requirements.Q: What are the main benefits of using a polished pure copper sheet roll?

A: Using polished pure copper ensures optimal electrical and thermal performance, excellent corrosion resistance, and minimal maintenance. The polished finish also adds aesthetic value, useful for both structural and decorative purposes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Earthing Products Category

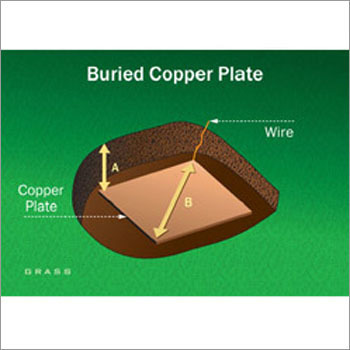

Copper Earthing Plate

Price 1900.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Copper Earthing Plate

Application : It is applied at homes, office, solar power plant, etc.

Material : Copper Bonded Steel

Color : Copper

Copper Bonded Earthing Rod

Price 1900.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Copper Bonded Earthing Rod

Application : It is applied at homes, office, solar power plant, etc.

Material : Copper Bonded Steel

Color : Copper

GI Hot Dip Strip

Price 36 INR / Meter

Minimum Order Quantity : 1 Meter

Product Type : Hot Dip Strip

Application : Industrial

Material : Galvanized Steel

Color : Silver

GI Earthing Strip

Price 60 INR / Meter

Minimum Order Quantity : 500

Material : other, Galvanized Iron

Color : Sliver

Send Inquiry

Send Inquiry